Every kegging system requires a regulator and a CO2 tank. These two are critical elements in your setup, and the co2 manifold allows connection to outputs from the Co2 regulator to the kegs. Individuals who want to experience different pressures per output can use dual output co2 regulators. CO2 tank manifolds also prove helpful in other applications that utilize carbon dioxide, whether liquid or gas, such as entertainment aspects like creating special effects to stimulate the environment. This article provides more information about Co2 tank manifolds and how they function.

What is a Co2 Manifold?

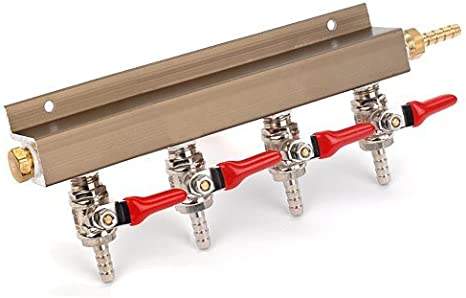

A Co2 manifold plays an essential distribution role, allowing multiple kegs to connect to one Co2 tank or in other uses that require co2, multiple outputs from one co2 tank. The number of kegs varies with the units; some have two kegs while others feature six taps.

The manifold also helps to separate outputs in commercial kegerators and homebrew systems, acting as a splitter in the configuration. It guarantees no pressure interruptions in the system when one tap is turned off individually (depending on type of manifold setup).

https://www.shutterstock.com/image-photo/seamless-bottle-group-storage-oxygen-argon-1889543683

Using a Co2 tank manifold also eliminates the worry of beer flowing backward when a check valve is included. Depending on type of co2 tank manifold setup you get, it may include check valves in every outlet to prevent back flow in the setup.

Can You Daisy Chain Co2 Tanks?

It is possible to daisy chain Co2 tanks. However, it is essential to pay close attention to the setup since a lot can go wrong when there are two, or more, carbon dioxide tanks in one configuration. When setting up, ensure the tanks are on two opposite sides and the daisy chains are correctly connected.

One of the most common complications experienced when we tried to daisy chain Co2 tanks was the pressure properties. The setup’s performance deteriorates if one of the tanks goes out before the other. It will result in the half-full tank refilling the empty one, affecting the entire system. Re-configuring the whole chain is necessary to restore standard performance. Including 90-degree turns in the system will limit the flow of carbon dioxide to all jets and decrease the gas pressure.

https://www.shutterstock.com/image-photo/carbon-dioxide-cylinder-pack-use-welding-1901258470

Placing both Co2 tanks on one side of the setup also contributes to several complications in a daisy chain setup. We recommend the two Co2 tanks on one side only when there is a long run of Co2 jets. The two tanks will ensure gas gets up to the final valve with the necessary pressure to facilitate functioning. The jets can also run on individual tanks. It means that the failure of one tank will not affect other Co2 jets in the setup.

Where Can I Get a Co2 Manifold?

Co2 manifolds are widely available in the market. Numerous online shopping platforms and accessory shops have different brands of Co2 manifolds on sale at competitive prices. We recommend thorough market research that includes price and feature comparison before settling on a Co2 tank manifold for your system. The following section has ideal options to consider when searching for a Co2 tank manifold.

Which Co2 Manifolds Should I Consider Buying?

YaeBrew Co2 Gas Manifold

The YaeBrew Co2 gas manifold system guarantees quality and reliability. It ensures superior quality results and effectively maintains the pressure and carbonation for the different kegs in the setup. The Co2 manifold 2 way system has an aluminum body fitted with 5 and 16-inch outlets and check valves. These valves facilitate individual shutoff while preventing beer system failure.

YaeBrew 3 Way Co2 Gas Manifold

YaeBrew is a dominant brand in this niche and the YB 3-way Co2 gas manifold features in their catalog. It is a Co2 manifold 3 way system that proves effective for commercial businesses and small-scale breweries. The aluminum body, 16-inch outlets, and a reliable splitter are some outstanding features guaranteed by this unit. Check valves built in the beer coupler help prevent check valve failure and beer system failure.

Bev Rite Co2 Manifold

The Bev Rite Co2 manifold 6 way is another worthy option to consider. It allows users to run up to six multiple lines from one Co2 tank. The units also feature an extension plug, making it possible to connect another manifold to expand the setup. We recommend observing the maximum operating pressure to avoid leakages and even complete system failure when using the unit.

Co2 Stage Effects Manifold

Co2 stage effects manifolds are common in the nightlife environment. The manifold system allows management to stimulate the environment and create a fun vibe by adding fog and extra lighting. The features available are relative to each design; the more features a unit guarantees, the higher its price and power consumption. Common locations where Co2 stage manifolds can be found include outdoor concerts, club parties, wedding ceremonies, and music festivals.

What To Know About Co2 Cylinder Manifolds?

It is a Liquid/Gas Mix

It is essential to understand that Co2 containers contain around 70% liquid content. The 70% fluid is liquidized carbon dioxide. However, specific uses of the element require it in a gas state. The liquid needs to vaporize before allowing sufficient usage at the required rate.

Withdrawal Rates Vary

Numerous factors play significant roles when withdrawing gas from a cylinder. For a maximum temperature of 70 degrees Fahrenheit, the industry-standard rate per hour is 50 scfh in standard-sized containers. The amount of gas released from the setup is directly proportional to the number of cylinders. The temperature around the tank can also affect withdrawal rates.

Pressure and Gas Flows

The pressure in the cylinder might increase if the temperature surrounding the setup increases. On the other hand, a decrease in ambient pressure will result in a reduction in-cylinder pressure. To avoid these fluctuations, we advise sheltering the tanks from outdoor elements.

Conclusion

In conclusion, installing the setup correctly is crucial to achieve the safest and most efficient Co2 tank manifold configuration. Ensure it is a climate-controlled location to avoid pressure and temperature fluctuations. Brewers are better positioned to prevent mishandling of Co2 tanks and reduce the handling of individual cylinders and kegs. The prospects shared in this article are worthy purchases to consider when creating your Co2 distribution system.